There will come a point when we can now longer blame supply chain shortages and lack of labor for declining construction productivity and rising costs. The recent challenges we’ve faced underscore the fact that the residential construction industry is ripe for disruption.

HD Surveying and Geolocation

Between the 1990s and the mid-2000s, surveyors began to combine GPS and drone technology, dramatically impacting the land surveying profession. What once required teams of people on months-long expeditions can now be done with one or two people–who sometimes work entirely remotely–without setting foot on the land being measured and mapped. The cost of new techniques that incorporate high-definition photography, 3-D laser scanning, geographic information systems has come down substantially, meaning the surveying process will become even more automated.

Benefits: accuracy and speed further improved

5-D BIM Technology

Early architectural concepts and designs have traditionally been little more than sketches and loose floor plan ideas. Now, 5D BIM (five-dimensional building information modeling) allows design teams to create virtual models that demonstrate how changes to materials, layouts, square footage and other design elements not only affect the appearance of a facility, but also the cost and schedule of construction.

Benefits: predictability, accuracy, real time data and updates when changes are made

Digital Collaboration and Mobility

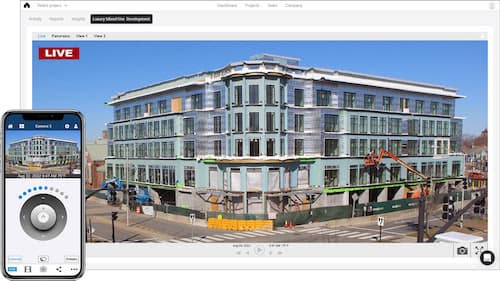

Moving away from paper blueprints, design drawings, purchase orders, progress reports and punch lists and toward online, real-time sharing of information will soon be a norm instead of a novelty. A seamless real-time experience can easily and effectively be applied across mutliple facets, such as design management, materials management, scheduling, quality control, crew tracking, and more.

Benefits: transparency and collaboration, timely progress and risk assessment, quality control, change order tracking, better and more reliable outcomes

IoT and Advanced Analytics

On a construction site, the Internet of Things allows construction equipment and materials to “talk” to a central data platform to capture critical performance parameters. Sensors, near-field-communication (NFC) devices, and other technologies can help monitor productivity and reliability of both staff and assets.

Benefits: automated maintenance alerts, inventory management, ability to test strength, reliability and energy efficiency of the structure, ability to monitor jobsite safety

Construction Material Innovations

3D Printing is already used in many industries for prototyping, product development, and production and has begun to make its mark in home building. According to Straits Research, the global 3D printing construction market size was worth USD 10.94 million in 2021. It is expected to reach USD 47.95 million by 2030. Construction 3D printing is a technique for creating construction elements or entire buildings by layering concrete, polymer, metal, or other materials on a 3D printer. The most common printer extrudes concrete back and forth using a robotic arm.

Other materials showing promise for eventual mainstream adaptation include Aerogel, a super-transparent, super-insulting material that is 99.98 percent air. Nanomaterials—super-strong, ultra-lightweight materials now in the testing stage may be viable substitutes for steel reinforcement in structures and foundations. New ideas being tested by the concrete industry include the use of bacteria as a healing agent to close cracks in concrete, using a layer of “concrete cloth” to create drains and channels that are set in place by simply adding water, and cement that can absorb 4,000 liters of water a minute.

Benefits: shorter lead times, greater design freedom, less labor required, reducing logistical processes, reducing waste

Robotics On and Off the Site

Robots have already proven their ability in laying brick, tying rebar and lifting heavy objects to place them in exact coordinates. As prefabrication of walls and other structures begins to happen inside of factories more and more, robotics will play an expanded role.

Benefits: faster construction requiring fewer laborers, improved safety and accuracy, susceptibility to weather conditions minimized, waste reduction

STAYING SAVVY:

Technological advancements have already begun to change expectations and processes. Over the next decade, researching and implementing construction technology will be key to the sustainability of a homebuilder’s business model.